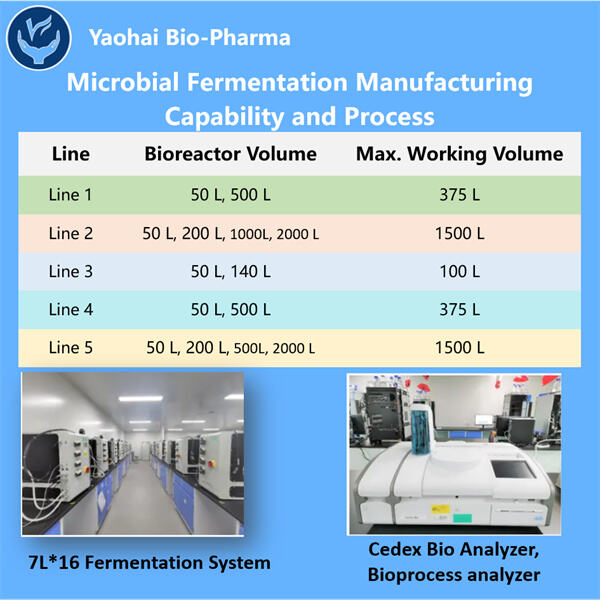

Mikrobielle Fermentation ist der Vorgang, bei dem kleine Lebewesen wie Hefen und Bakterien in der Lage sind, andere Produkte herzustellen. Diese Yaohai CDMO für mikrobielle Fermentation sind mikroskopische Wesen, die das bloße Auge nicht wahrnehmen kann, aber bei der Zubereitung und Verarbeitung von Lebensmitteln sehr wichtig sind. Sie bilden Verbindungen aus, die Zuckerverbindungen abbauen, nämlich Alkohol, Säuren und Gase, wenn sie Zuckernahrung aufnehmen. Diese neu entstehenden Stoffklassen sind bedeutsam, da sie zur Herstellung vieler Lebensmittel und Getränke beitragen, die wir kennen und lieben.

Offensichtlich gibt es eine große Vielfalt an Anwendungen der mikrobiellen Fermentation in vielen verschiedenen Branchen. Insbesondere im Bereich Lebensmittel und Getränke, Medizin oder einfach in der chemischen Industrie. Dieses Yaohai Hochleistungs-Plasmid-Gärung ermöglicht uns viele leckere Dinge wie Brot, Käse, Joghurt, Gurken und Essig usw.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN