Prilagođavanje, Efikasnost & Kostefikasanost

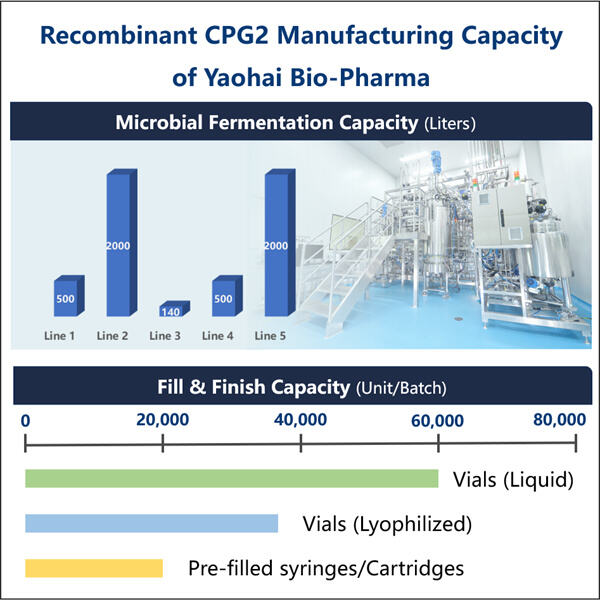

Carboxypeptidase G2 Manufacturing ima iskustva u proizvodnji bioloških sredstava koji su izvedeni iz mikroorganizama. Ponuditi prilagođena R i D rješenja te rješenja za proizvodnju, dok se minimizira rizik. Eksperimentirali smo s različitim tehnikama, poput rekombinantnih celijaskih podjedinica čak i vakcina (uključujući peptide), rastuće faktore, hormone i citochine. Specializirali smo se na više mikroorganizama kao što su kvasinice izvanćelijasko i unutarćeljsko sekretiranje (dobitnost do 15g/L) i bakterije unutarćeljsko rastvorljivo i inkluzioni tijela (dobitnost do 10g/L). Također imamo BSL-2 fermentacijsku platformu za razvoj bakterijskih vakcina. Stručnjaci smo u poboljšanju procesa, povećanju dobavnosti proizvoda i smanjenju troškova proizvodnje. S učinkovitim timom tehnologije, osiguravamo vremensko i kvalitetno dostavljanje projekata i donošenje vaših proizvoda na tržište brže.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN