على الرغم من العقبات التي قدمتها هذه الدراسات القليلة،但从 المهم فهم أن الكولاجين مهم للبروتينات ولديه العديد من الأدوار الفسيولوجية. فهو يملأ الفراغ بين العظام والجلد والغضاريف والأوتار وما إلى ذلك. الكولاجين مثل الهيكل الذي يربط الأمور معًا. هذا ما يسمح لجسمنا بالعمل وإجراء جميع الحركات والأنشطة البدنية التي نرغب في القيام بها. ياوهاي إنتاج الكولاجين من النوع الثالث المُعدّل وراثيًا هو أحد أنواع الكولاجين العديدة. إنه نوع من الكولاجين الموجود بكثرة في الجلد والأوعية الدموية والأعضاء الموجودة في تجويف البطن. وهذا مهم جدًا لأن الكولاجين من النوع الثالث يساعد في الحفاظ على وظائف هذه المناطق في الجسم. وإذا لم يتم إنتاجه بشكل صحيح، فإنه يمكن أن يؤدي إلى العديد من الأمراض ويضر بصحتنا العامة.

يتم معالجته لإنتاج الكولاجين من النوع الثالث، وهو ليس عملية بسيطة وتتطلب العديد من الخطوات. هذا هو الجزء الصغير، البروكولاجين الذي يبدأ منه كل شيء. البروكولاجين هو مكون أساسي. يتكون من ثلاث سلاسل من الأحماض الأمينية ملفوفة حول بعضها البعض مثل الحبل. يتجمع قطعتان من البروكولاجين مع بعضهما البعض لإنتاج بنية تُعرف بالحلزون الثلاثي وتسمى الكولاجين من النوع الثالث.

ياوهاي عملية إنتاج الكولاجين البشري المُعاد تشكيله لا يبقى داخل الخلية، بل ينتشر خارج الخلية استعدادًا للتغيرات اللاحقة في الخارج. بعد كل شيء، يحتاج إلى الخروج من الخلية حتى يتمكن بعض البروتينات الخاصة التي تسمى الإنزيمات من قطع الكولاجين إلى أجزاء أصغر. يمكن لهذه الأجزاء الصغيرة من الكولاجين من النوع الثالث أن تتجمع معًا لتشكيل شبكة شبيهة بالشبكة الكبيرة التي تشكل إطارًا للأنسجة، مثل نوع من الشباك الطبيعي للأمان

واحد من أهم الإنزيمات لإنتاج الكولاجين من النوع الثالث هو... كما تخمينك، إنزيم. تخيل الإنزيمات كمساعدين سيقومون بتسهيل الأمور ليحدث كل شيء بسلاسة. واحد منها هو إنزيم PIIINP. هذا الإنزيم أساسي لحفظ حلقة ثلاثية الكولاجين بحيث تظل قوية وصلبة ومتماسكة.

بالإضافة إلى هيلاس، هناك الكولاجيناز. من ناحية أخرى، الكولاجيناز تقطّع الكولاجين إلى أجزاء مكونة قد تساعد في إصلاح أو إعادة بناء الأنسجة المصابة. ومع ذلك، فإن الكثير من الكولاجيناز ليس مثاليًا، فقد يكون ضارًا ويسبب أشياء مثل التليفات، حيث يصبح النسيج سميكًا بشكل غير طبيعي أو متشابكًا. لذلك، ياوهاي الكولاجين III المُعاد تشكيله والخالي من الجراثيم شيء مهم.

يقوم الجسم البشري بتنظيم كمية الكولاجين من النوع الثالث التي يعبّر عنها عن كثب. لديه مجموعة مختلفة من الإشارات والمسارات لضمان إنتاج الكمية المناسبة من الكولاجين في الوقت المناسب. هذا هو السبب في أن ياوهاي عملية إنتاج الكولاجين البشري المُعاد تشكيله عملية أساسية.

الكولاجين من النوع الثالث هو الأكثر وفرة والأهم، لكن إنتاجه يعتمد بشكل كبير على الهرمونات (الأستروجين / التستوستيرون)، لذلك يتم إنتاج كميات مختلفة منه في أجزاء مختلفة من الجسم. على سبيل المثال، الأستروجين قد ثبت أنه يعزز نمو الكولاجين في الجلد، مما يؤدي إلى جلد أكثر صحة ومرونة. وهنا يأتي دور ياوهاي تصنيع الكولاجين المُعاد تشكيله من النوع الأول يلعب دوره.

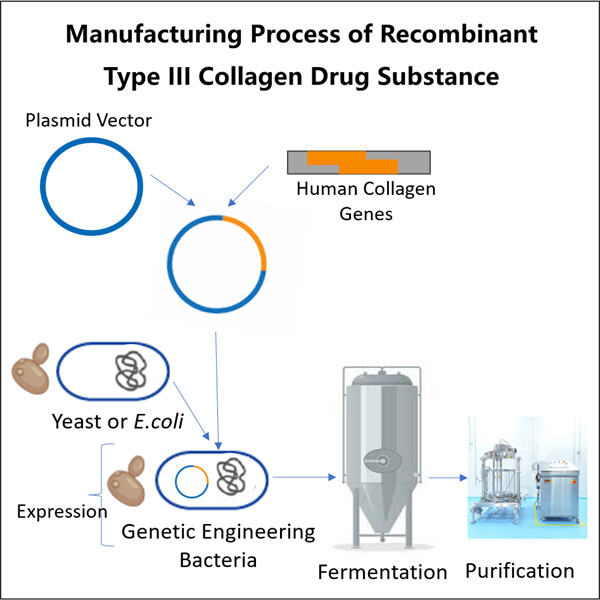

ياوهاي بايو-فارما، الرائدة في عملية إنتاج الكولاجين من النوع الثالث باستخدام الأحياء الدقيقة، تقع في جيانغسو. نحن نركز على العلاجات واللقاحات المنتجة ميكروبيًا والتي تناسب إدارة الصحة البشرية والبيطرية وصحة الحيوانات الأليفة. لدينا منصات تقنية حديثة للبحث والتطوير والإنتاج تغطي العملية بأكملها، من هندسة سلالات الميكروبات، وبنوك الخلايا، وتطوير العمليات والطرق، وحتى التصنيع السريري والتجاري، مما يضمن لنا توفير الحلول الأكثر تقدمًا بنجاح. لقد اكتسبنا خبرة كبيرة في مجال معالجة الأحياء الدقيقة البيولوجية. تم إكمال أكثر من 200 مشروع بنجاح، ونساعد عملائنا على التغلب على اللوائح مثل لوائح إدارة الغذاء والدواء الأمريكية (FDA) وإدارة الأدوية الأوروبية (EMA). كما نساعد العملاء مع إدارة الأدوية الأسترالية (TGA) وإدارة المنتجات الطبية الوطنية الصينية (NMPA). يمكننا الاستجابة بسرعة لمتطلبات السوق وتوفير خدمات CDMO المخصصة بفضل خبرتنا ومهارتنا.

تتخصص Yaohai Bio-Pharma في عملية إنتاج الكولاجين من النوع الثالث باستخدام المنتجات البيولوجية المستخلصة من الميكروبات. نقدم حلول تخصيص البحث والتطوير وكذلك التصنيع مع تقليل المخاطر. لقد شاركنا في العديد من الأنواع مثل اللقاحات الفرعية المركبة، الهرمونات الببتيدية، السيتوكينات عوامل النمو، الأجسام المضادة ذات المجال الواحد، الإنزيمات، الحمض النووي البلازميدي، الرنا المرسال والمزيد. نحن خبراء في عدة مضيفات دقيقة مثل الخميرة داخل الخلية وخارجها (إنتاج يصل إلى 15 جراماً لكل لتر)، إفراز بكتيري بيروبلسمي بالإضافة إلى الجزيئات القابلة للذوبان داخل الخلية (إنتاج يصل إلى 10 جرامات/لتر). بالإضافة إلى ذلك، قمنا بتطوير منصة تخمير ميكروبية المستوى BSL-2 لتطوير لقاحات بكتيرية. لدينا سجل حافل في تحسين العمليات الإنتاجية مما يؤدي إلى زيادة الإنتاج وتقليل التكاليف. ومع فريق تقني كفؤ للغاية، نضمن تسليم المشاريع بشكل سريع وموثوق ونجلب منتجاتكم إلى السوق بشكل أسرع.

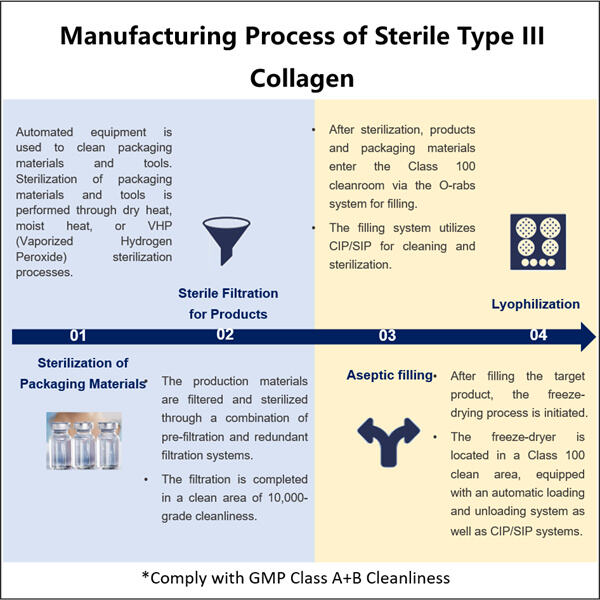

ياوهاي بيوفارما، وهي شركة CDMO مicrobial لإنتاج الكولاجين من النوع الثالث، تدمج الشؤون التنظيمية وإدارة الجودة. لدينا نظام جودة متوافق مع معايير GMP الحالية، وكذلك اللوائح في جميع أنحاء العالم. فريقنا التنظيمي على دراية بالإطارات التنظيمية العالمية لتسريع إطلاق المنتجات البيولوجية. نحن نتأكد من أن عمليات الإنتاج قابلة للتعقب، وأن المنتجات ذات جودة عالية وتتوافق مع لوائح FDA الأمريكية وEMA الأوروبية. كما يتم الالتزام بمعايير TGA الأسترالية وNMPA الصينية أيضًا. لقد نجحت ياوهاي بيوفارما في اجتياز التدقيق الميداني من قبل الشخص المؤهل (QP) في الاتحاد الأوروبي لضمان نظام الجودة الخاص بنا وموقع الإنتاج وفقًا لنظام GMP. كما اجتازنا أيضًا عمليات التدقيق الأولية لنظام إدارة الجودة ISO9001 ونظام إدارة البيئة ISO14001.

ياوهاي بايو-فارما، واحدة من أكبر 10 شركات لإنتاج نوع الكولاجين الثالث باستخدام عملية إنتاج المنتجات البيولوجية، هي متخصصة في التخمير المجاري. لقد أنشأنا منشأة حديثة تمتلك قدرات بحث وتطوير قوية وبنيات تحتية متقدمة. هناك خمس خطوط إنتاج للأدوية التي تتوافق مع معايير GMP لتنقية وتخمير الخلايا الدقيقة، بالإضافة إلى خطين لتعبئة الأنبوب وزجاجات الفلين المسبقة الملء. تتراوح أحجام التخمير المتاحة بين 100 لتر و2000 لتر. مواصفات التعبئة للزجاجات تتراوح بين 1 مل و25 مل، بينما تكون متطلبات التعبئة للحقن أو القوارير المسبقة الملء بين 1-3 مل. ورشة الإنتاج معتمدة حسب معايير cGMP وتقدم عينات تجارية وسريرية. الجزيئات الكبيرة المصنعة في منشأتنا متاحة للتوزيع عالميًا.