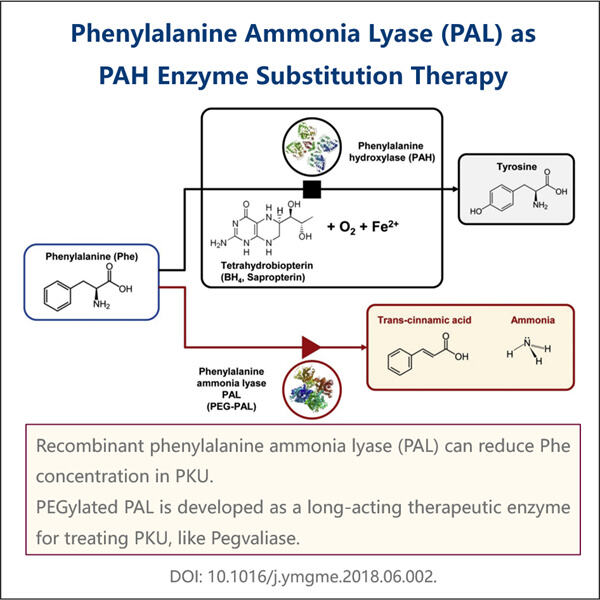

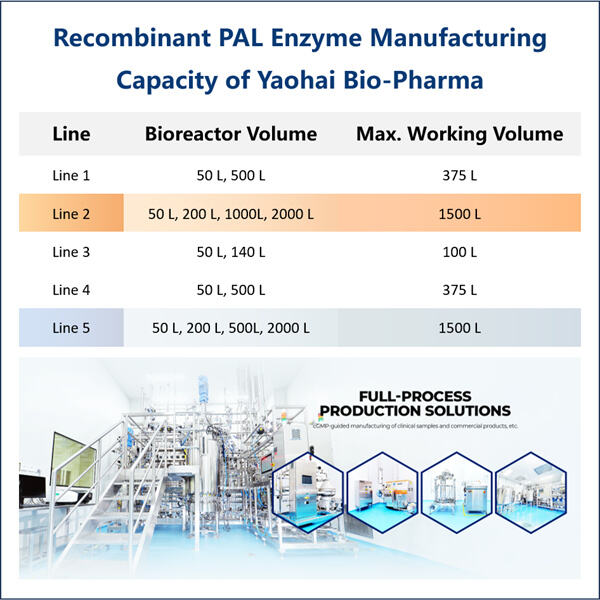

Some may not be familiar with Phenylalanine Ammonia Lyase (PAL). PAL is a type of special protein known as an enzyme that's used in the production of various products. These products can be health foods, vitamins, and others. One company that produces PAL is known as Yaohai. They are extremely dedicated to providing quality pal and in this article we cover how they produce pal and how they can present pal in diverse fashions.

The first step in making PAL is to grow special cells that will produce it. Those cells need to be properly nurtured, and that means eating good food, such as sugar, proteins, and vitamins, so they can grow strong and healthy. It’s a little like planting a garden, you have to ensure that the plants have the right nutrients to sprout. Once the cells are large enough, we then add the PAL inducers. These are helper cells that stimulate the cells to create more PAL. These helpers must be safe for people to eat and use.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NĒ

NĒ

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN