Circular RNA, or circRNA, is a specific kind of RNA that has a different shape. Whereas normal RNA has a linear straight-line appearance, circRNA is looped. CircRNAs — a type whose structure is crucial because they usually turn out to be abundant and participate in a lot of important cellular processes. For one thing, they regulate how our genes are expressed, which can influence everything from our body’s growth patterns to how we respond to disease. CircRNAs are of great interest to scientists; better understanding of them can reveal how diseases develop and identify novel therapeutic approaches. But there is a problem: circRNAs are very small and tend to be present in very low quantities in the samples scientists study. This makes it challenging to harvest enough circRNA for research.

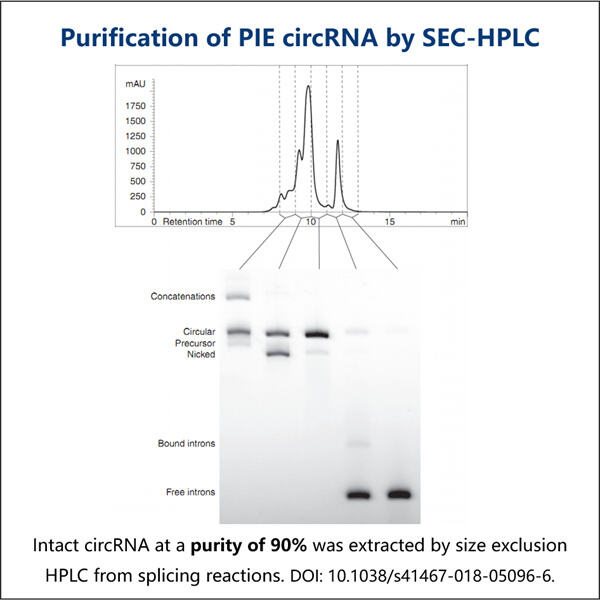

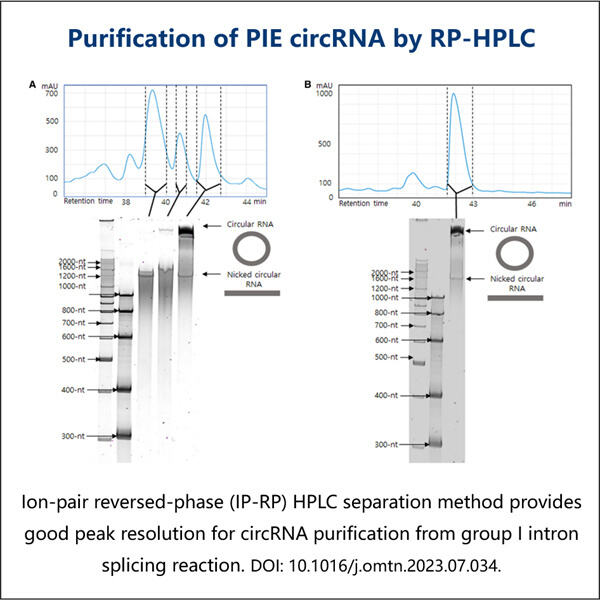

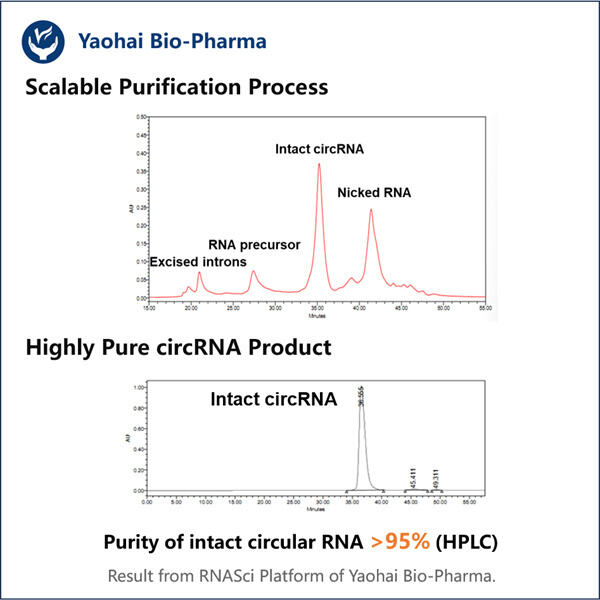

Before the definitive foundation was established to collect circRNA, a well-established method called High-performance liquid chromatography, or HPLC in brief, was utilized. HPLC is a versatile technique used for separating various molecules according to their physical and chemical characteristics. It operates by separating molecules based on size and shape. Because circRNAs are very small, they can be easily lost amid the thousands of other molecules in a sample. It means circRNAs can be separated out from other RNAs, proteins and exogenous debris that may have been included in the sample by using effective methods such as size exclusion chromatography (SEC), a HPLC technique. It's an important separation for scientists who need to isolate the circRNA for their research.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NĒ

NĒ

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN