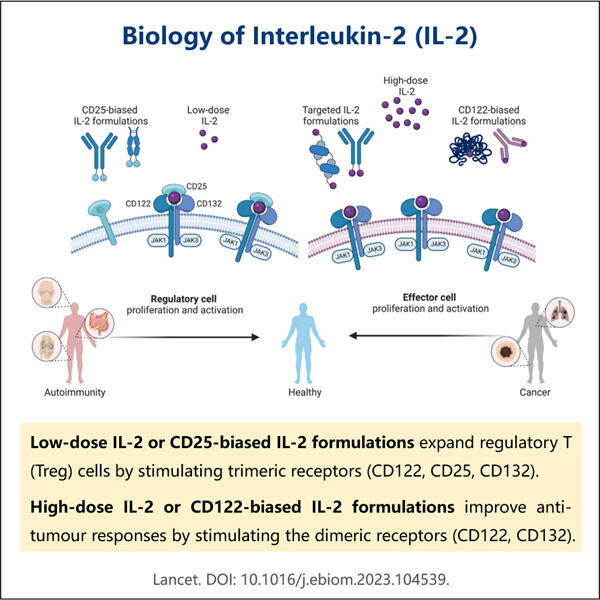

If you get ill, you might go to a doctor, or a hospital — and they strive diligently to help alleviate your symptoms. Doctors and scientists are constantly trying to find other ways for people who are sick in order to get well with medicines. Among the types of ヒトインスリンイソファン medication they zero in on are interleukins — one in particular is called Interleukin-2 often abbreviated as IL-2

IL-2 is a special type of protein that our bodies make naturally. This protein is essential in assisting our immune system to defend us against diseases. However, in some cases our own bodies may not make sufficient amounts of IL-2. Hence it is essential for manufacturing in a lab or factory which provides additional help to the people when required

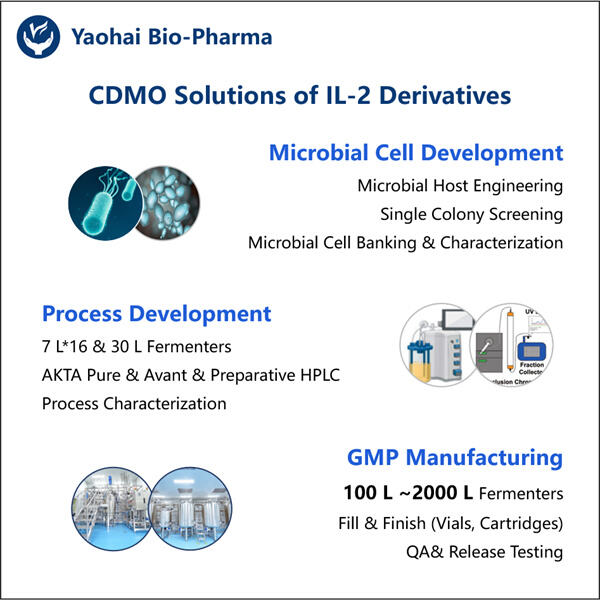

Creating IL-2 in a lab or factory is cumbersome, but it saves lives. First, Yaohai grows cells in a lab. Thus, these cells are miniature factories capable of multiplying into more cell they can reproduce. Once these インターロイキン 2 1 cells have grown adequately, the scientist collect them and harvest the IL-2 from these cells

A series of purifications follows each IL-2 to remove contaminating molecules. This includes bringing nature into the home and ensuring that pets are removed from dangerous substances. This is important to make sure tales of a “miracle drug” do not put patients who could genuinely benefit from it at stake.

Yaohai knows IL-2 切断型プラスミン is crucial and needs to be made quickly and easily. Capital takes advantage of modern, cutting-edge technologies that help further streamline the production process. In this way, they can ensure that the drug reaches people who need it much faster whilst those waiting for treatment cannot afford to wait.

Another of their impressive techniques for this is by employing a bioreactor system. This allows them to produce much more IL-2 than they could in a small lab. The bioreactor, which is in essence a sealed container that can create the perfect environment for cells to grow. This allows the cells to produce a lot of IL-2 in half as long time, which makes it important to serve many patients.

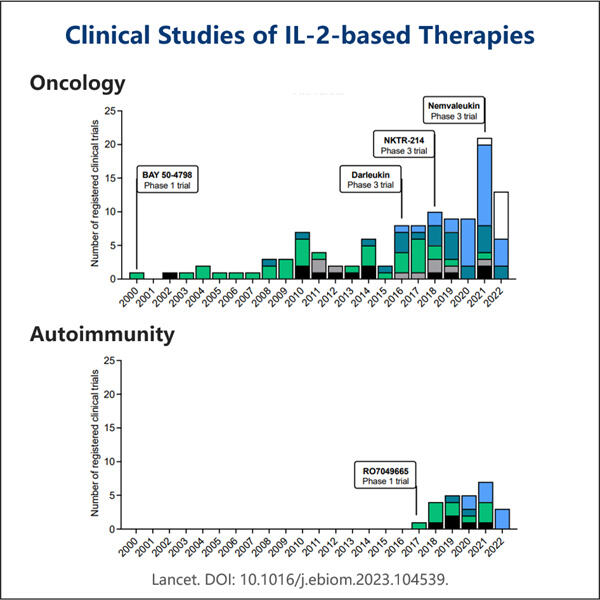

Overall this technique to manufacturing IL-2 has huge potential for future medicines. Immune-based therapies, such as IL-2, are gaining prominence in the treatment of a number of diseases, including cancer. In other words, the type of work leaders like Yaohai are doing can translate into life changing efforts for millions.

Yaohai Bio-Pharma is a leading in microbial biologics CDMO. Our primary focus is the production of microbial vaccinations and therapeutics for managing pets, human and Interleukin-2 (IL-2) Manufacturing. We are equipped with cutting-edge RD platforms as well as manufacturing technologies that encompass the entire process beginning with the development of microbial strains and cell banking, to method and process development, to clinical and commercial manufacture that ensures the successful supply of new solutions. Through the years, we have accumulated vast knowledge of microbial-based bio processing. Over 200 projects have been successfully completed and we assist our clients to get through regulations, such as those of the US FDA and EU EMA. We also assist them in navigating Australia TGA and China NMPA. We are able respond promptly to market demands and offer tailored CDMO services thanks to our experience and expertise.

Yaohai BioPharma は、品質管理とインターロイキン-10 (IL-2) 製造を組み込んだ上位 2 位の微生物 CDMO です。当社は、世界中の現在の GMP 基準と規制要件に準拠した強固な品質システムを開発しました。当社の規制チームは、生物学的製品の発売を迅速化するための世界的な規制フレームワークに精通しています。当社は、高品質の製品で製造プロセスが追跡可能であること、および米国 FDA と EU EMA の規則に準拠していることを確認します。オーストラリア TGA と中国 NMPA も準拠しています。Yaohai BioPharma は、欧州連合の資格者 (QP) が実施した GMP プロセスと製造施設の検査に合格しました。また、ISO9001 品質管理システムと ISO14001 環境管理システムの初期認証監査も合格しました。

Interleukin-2 (IL-2) Manufacturing has experience in manufacturing biologics that are that are derived from microorganisms. We provide tailored RD as well as manufacturing solutions, while minimising the risk. We have experimented with a variety of techniques, such as recombinant cellular subunits of vaccines (including peptides), growth factors, hormones and the cytokines. We have specialized in multiple microorganisms like yeast extracellular and intracellular secretion (yields up to 15g/L) and bacteria intracellular soluble and inclusion bodies (yields up to 10g/L). We also have the BSL-2 fermentation platform to develop bacterial vaccines. We are experts in improving processes, increasing product yields, and decreasing production costs. With an effective technology team, we ensure timely and quality project delivery and bring your products to market faster.

Interleukin-2 (IL-2) Manufacturing is a Top 10 biotech company specializing in microbiological fermentation. We have built a modern facility with strong RD capabilities and modern manufacturing facilities. Five production lines for pharmaceuticals in line with GMP standards for microbial purification and fermentation along with two automated fill and finish lines for vials and cartridges and pre-filled needles are available. The fermentation scales available are 100L, 500L, 1000L, to 2000L. Specifications for filling vials range from 1ml up to 25ml. the pre-filled syringes and cartridge filling specifications cover between 1-3ml. The workshop for production is cGMP compliant, and guarantees a stable supply of commercial products and clinical samples. Our factory produces large molecules that are shipped around the world.