Minőségbiztosítás GMP Tuberkulózis (TB) Antigen Gyártásban

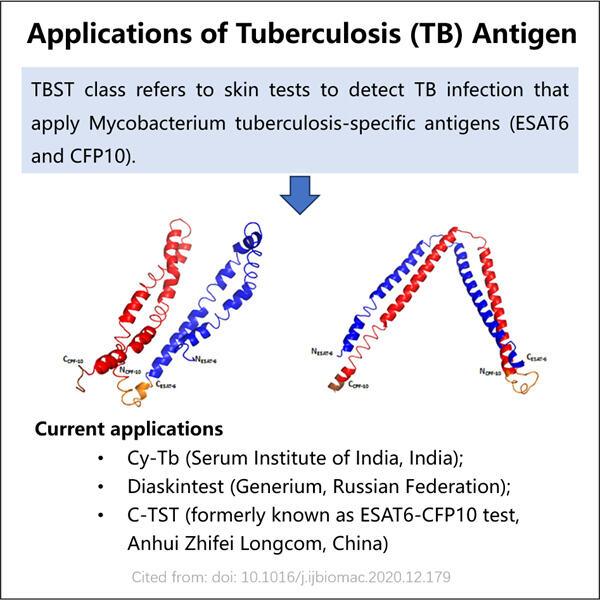

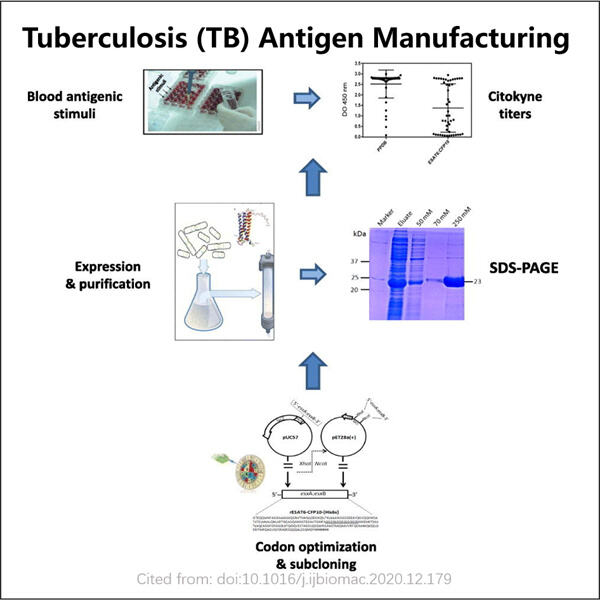

A tudósok nagyon közel kell lenniük a szabályokhoz a GMP Tuberkulózis (TB) Antigen előkészítésekor. Ez a jó ítéletszámítás része a minőségbiztosításnak. Egy recept használatával, hogy biztosítsuk a magas minőségű teljesítményt, a szakemberek ismétlik a GMP Specifikációk Tuberkulózis (TB) Antigen eljárását sokszor, gyakran 20-50 alkalommal a termelés során. HttpServletSummary A tudósok minden tételt különböző módon tesztelnek a GMP Tuberkulózis (TB) Antigenben, hogy biztosítsák, hogy megfeleljen a várakozásoknak.

Ők azt is biztosítják, hogy a gépeik és eszközök, amelyeket munkáskor használnak, tisztességesen megmaradnak és rendben vannak. Ez fontos, mivel garantálja a GMP Tuberkulózis (TB) Antigen tisztaságát és összetételét, valamint bármilyen toxikus anyagot eliminiál. Mivel bármi rosszra fordulhat és kockázatot jelenthet az emberek számára, a tudósok mindenkit figyelmesen figyelnek!

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN