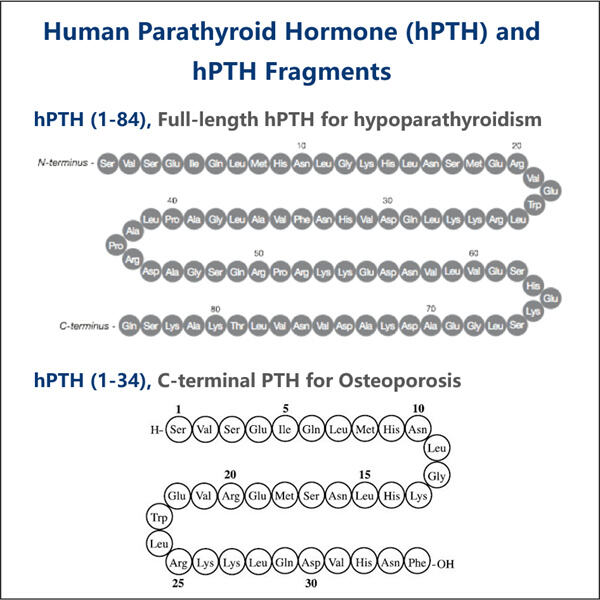

재조합은 다양한 구성 요소를 결합하는 것을 의미합니다. PTH- 부갑상선 호르몬 1: 우리 몸에서 칼슘 수치를 조절하는 역할을 하는 호르몬입니다. 다음으로, 우리 모두가 "제조"라는 단어가 무엇인지 알고 있습니다. 기계와 기술로 무언가를 만드는 것입니다. 이 모든 단어를 합치면 Yaohai가 됩니다. 재조합 돼지 인슐린 바이오제조 그리고 기계를 이용해 부갑상선 호르몬을 만드는 것, 그 부분들을 똑똑하게 결합하는 것으로 정의할 수 있습니다.

PTH는 과학자들이 수년간 구축한 재조합형으로 다시 새로운 것입니다. 이것은 박테리아라는 작은 유기체에서 사용되며 부갑상선 호르몬을 개발하기 위해 특정 단백질을 사용합니다. 이러한 시장 리더 중 하나는 Yaohai입니다. 그들은 재조합형 PTH에 대한 독창적이고 혁신적인 공정을 개발했습니다.

박테리아를 요리하기 위해, 그들은 먼저 DNA(작은 벌레들에게 언제, 어디서 켜야 하는지 알려주는 마법의 요리책)를 휘젓습니다. 그런 다음, 그들은 이 DNA를 박테리아에 넣습니다. 그런 다음 그들은 실험실에서 이 박테리아를 키웁니다. 야오하이 GMP 재조합 펩타이드 제조 PTH 호르몬을 방출하여 우리와 똑같이 번식하고 더 많은 PTH를 만듭니다. 따라서 연금술은 이 호르몬을 많이 얻는 효과적인 방법입니다.

Supine PTH Productions 게다가, 이 리소스는 또한 소비자를 위해 PTH 품목 품질로 훨씬 더 예산 친화적인 기술을 생산하는 데 도움이 됩니다. PTH는 동물과 인간 PTH를 기반으로 하기 때문에 비용이 많이 드는 기존 방법을 통해 생산됩니다. 이는 특히 대량의 호르몬을 합성해야 할 때 시간이 많이 걸리고 리소스가 많이 필요한 접근 방식이 될 수 있습니다.

대조적으로, 재조합 PTH 제조는 박테리아를 사용하여 해당 호르몬을 만든다는 점을 제외하면 어렵고 비쌉니다. 재조합 PTH를 생성하는 새로운 프로세스는 더 빠르고 간단한 프로세스입니다. 이를 통해 각 의사는 취급 및 조달/투여에 비용이 들지 않으므로 PTH 치료를 할인된 가격으로 제공할 수 있습니다. 즉, 더 많은 사람들이 자격이 있는 도움을 받고 매우 비싼 비용에 대해 너무 걱정하지 않을 수 있습니다.

이것은 의학 분야의 획기적인 진전이라고 할 수 있으며, 재조합 PTH 제조가 있습니다. 이 방법은 치료에 필수적인 PTH 호르몬을 만드는 훨씬 쉽고 저렴한 방법을 제공합니다. 이제 환자는 비용이 얼마나 들 것인지에 대한 걱정 없이 치료를 받을 수 있습니다. 보도에 따르면, 이는 그러한 치료가 필요한 많은 사람들에게 큰 안도감을 주었습니다.

재조합 PTH도 예측이 가능하며, 이는 다음의 주요 이점으로 이어집니다. 기존의 PTH(예: 여러 출처에서 추출되어 종종 다름)와 달리 결과는 기존 PTH와 다를 수 있습니다. Yaohai 재조합 파킨 단백질 제조 통제된 환경에서 제조되므로 품질 결과가 매번 보장됩니다. 정기적인 치료가 필요한 환자는 이러한 일관성에서 진정한 가치를 볼 수 있습니다.

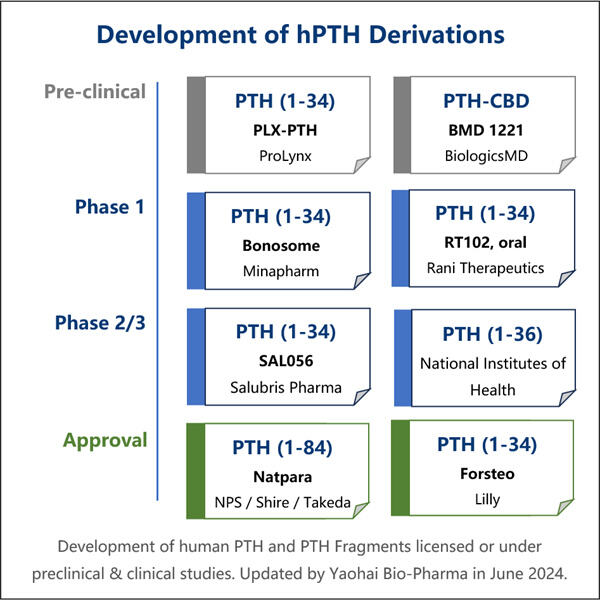

Yaohai Bio-Pharma는 재조합 PTH 제조 CDMO 분야의 선두 주자입니다. 당사의 주요 초점은 애완동물, 인간 및 수의학 건강을 치료하기 위한 미생물 백신 및 치료제 생산이었습니다. 당사는 미생물 균주 엔지니어링, 세포 뱅킹 처리 및 방법 설계, 임상 및 상업적 제조에 이르기까지 전체 제조 공정을 포괄하는 최첨단 RD 및 제조 기술 플랫폼을 보유하고 있어 가장 진보된 솔루션을 성공적으로 제공할 수 있습니다. 당사는 생물 처리 미생물 분야에서 엄청난 양의 지식을 축적했습니다. 200개 이상의 프로젝트가 성공적으로 완료되었으며 당사는 고객이 미국 FDA 및 EU EMA와 같은 규정을 준수하도록 돕습니다. 또한 호주 TGA 및 중국 NMPA를 탐색하도록 돕습니다. 당사는 경험과 전문성 덕분에 시장 요구 사항에 신속하게 대응하고 맞춤형 CDMO 서비스를 제공할 수 있습니다.

재조합 PTH 제조는 미생물에서 유래된 생물학적 제제를 제조한 경험이 있습니다. 우리는 위험을 최소화하면서 맞춤형 RD와 제조 솔루션을 제공합니다. 우리는 백신의 재조합 세포 소단위(펩타이드 포함), 성장 인자, 호르몬 및 사이토카인과 같은 다양한 기술을 실험했습니다. 우리는 효모 세포외 및 세포내 분비(수율 최대 15g/L) 및 박테리아 세포내 가용성 및 포함체(수율 최대 10g/L)와 같은 여러 미생물을 전문으로 했습니다. 또한 박테리아 백신을 개발하기 위한 BSL-2 발효 플랫폼도 보유하고 있습니다. 우리는 공정 개선, 제품 수율 증가 및 생산 비용 감소의 전문가입니다. 효과적인 기술 팀과 함께 우리는 시기적절하고 양질의 프로젝트 납품을 보장하고 제품을 더 빨리 출시합니다.

생물학적 제품의 상위 10대 생산자인 야오하이 바이오파마는 미생물 발효 분야의 전문 기업입니다. 당사는 현대식 시설과 강력한 RD 제조 역량을 갖춘 첨단 시설을 구축했습니다. 당사는 미생물 발효 및 정제에 대한 GMP 요건을 준수하는 100개의 약물 물질 제조 라인과 카트리지, 바이알, 사전 충전 주사기에 자동화된 500개의 충전-마무리 라인을 보유하고 있습니다. 사용 가능한 발효 규모는 1000L~2000L, 1L, 25L입니다. 비아용 재조합 PTH 제조는 1ml~3ml인 반면 사전 충전 주사기 및 카트리지 충전 사양은 XNUMX~XNUMXml를 포함합니다. 당사의 생산 워크숍은 cGMP를 준수하며 임상 샘플과 상업용 품목의 안정적인 공급을 보장합니다. 당사 공장은 전 세계로 운송되는 대형 분자를 생산합니다.

Yaohai BioPharma는 품질 관리와 규제 문제를 통합한 Top 10 Microbial CDMO입니다. 우리는 현재 GMP 표준 및 전 세계 규정을 준수하는 견고한 품질 관리 시스템을 개발했습니다. 당사의 규제 팀은 전 세계 규제 프레임워크에 대한 심층적인 이해를 가지고 있습니다. 이를 통해 생물학적 출시를 가속화할 수 있습니다. 우리는 추적 가능한 생산 프로세스와 고품질 제품을 보장하며 미국 FDA와 EU EMA의 지침을 준수합니다. 재조합 PTH 제조 및 중국 NMPA도 만족합니다. Yaohai BioPharma는 유럽 연합(QP)의 공인 자격자가 수행한 현장 감사를 성공적으로 통과하여 GMP 시스템과 생산 시설을 검토했습니다. 또한 ISO9001 품질 관리 시스템과 ISO14001 환경 관리 시스템의 첫 번째 인증 감사를 거쳤습니다.