Personalizare, Eficiență și Costuri Reduse

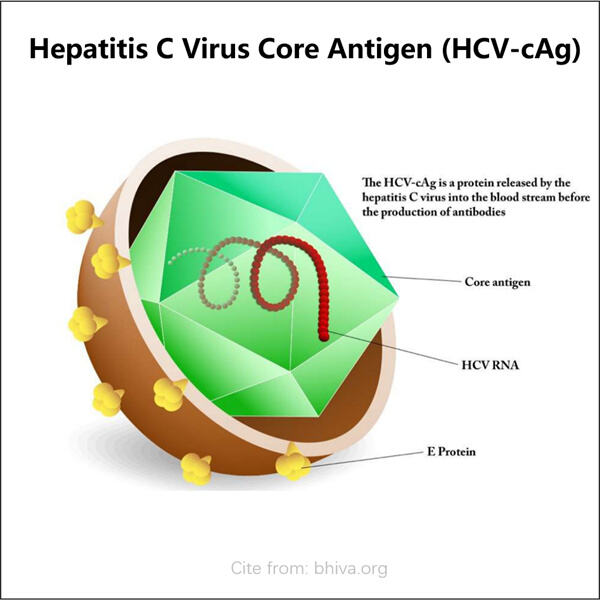

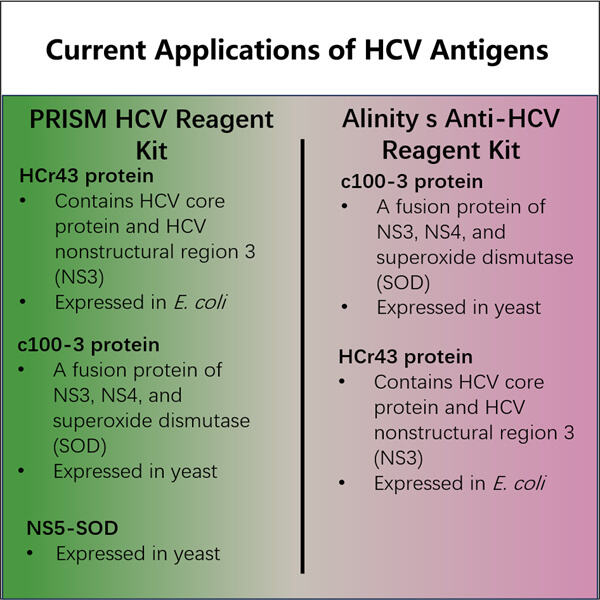

Yaohai Bio-Pharma are experiență în fabricarea de biologice create din microorganisme. Ofertăm soluții RD personalizate precum și servicii de producție, minimizând riscul. Am colaborat cu diverse modalități, cum ar fi vakine recombinante subunitare, peptide, hormoni, citocine, factori de creștere, antibody mono-domeniu, enzyme, ADN plasmidial, mRNA și altele. Ne-am specializat în mai multe microorganisme, cum ar fi levurile cu secreție extracelulară și intracelulară (rendiment până la 15g/L) și bacteriile cu soluble intracelulare și corpuri de incluziune (rendiment până la 10g/L). Am creat, de asemenea, un sistem de fermentație BSL-2 pentru a produce HCVcAg. Producem vakine. Suntem experți în optimizarea proceselor de producție, creșterea rendimentelor și reducerea costurilor. Avem o echipă tehnică foarte eficientă care asigură livrarea proiectelor în termen și cu cea mai bună calitate. Acest lucru ne permite să aducem produsele dvs. unice mai repede pe piață.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN