Llamas are one of those huge mammillary that everyone loves because they are so cute and fluffy. They're famous for their squishy fluff that makes so warm, snugly sweaters and blankets, along with big eyes like most of them are just really adorable. However, did you know that llamas are also helping scientists to develop new therapies for a range of diseases? We are very excited to explain to you the advantage of llama nanobodies and how they are transforming medicine.

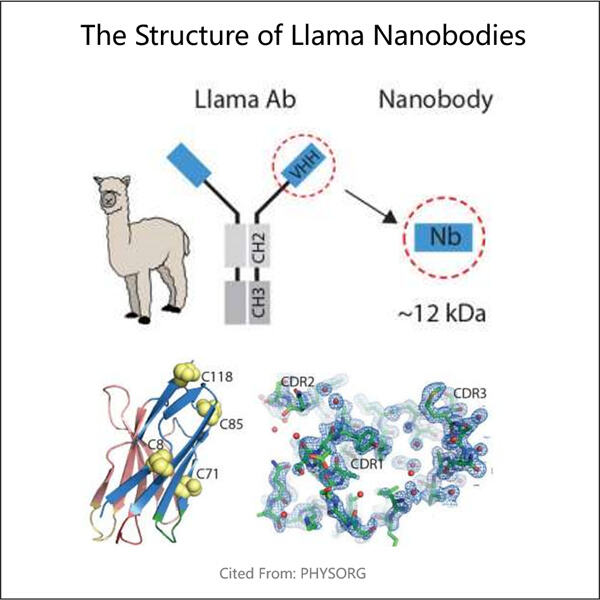

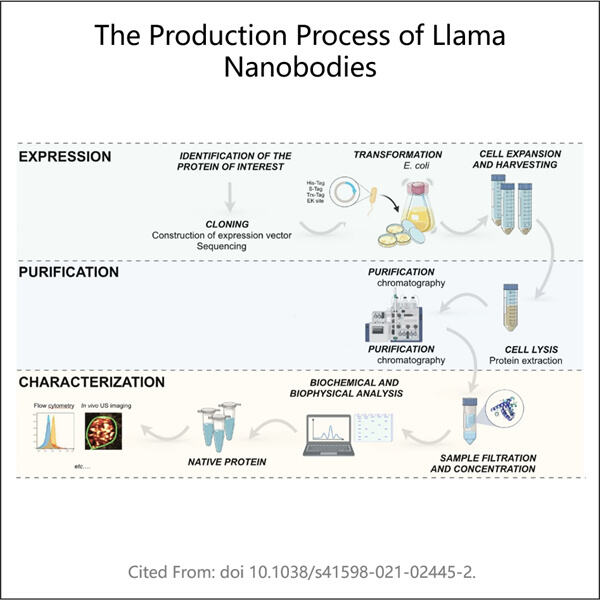

Nanobodies: Yaohai tiny proteins produced by llamas naturation that naturally occur. These Trijų specifinių nanokūnų gamyba are significantly smaller than the antibodies made by humans. Being smaller, they are also better able to locate and attach to particular ones in the body. Their special capability makes the most effective material for scientists also Nanobodies don't really get hurt because they are so powerful, and the heat does not affect them as nanobodies are super strong and stable. For this reason, stability plays a crucial role in facilitating these gens to function effectively at even the most arduous environments.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NE

NE

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN