Personalização, eficiência e relação custo-benefício

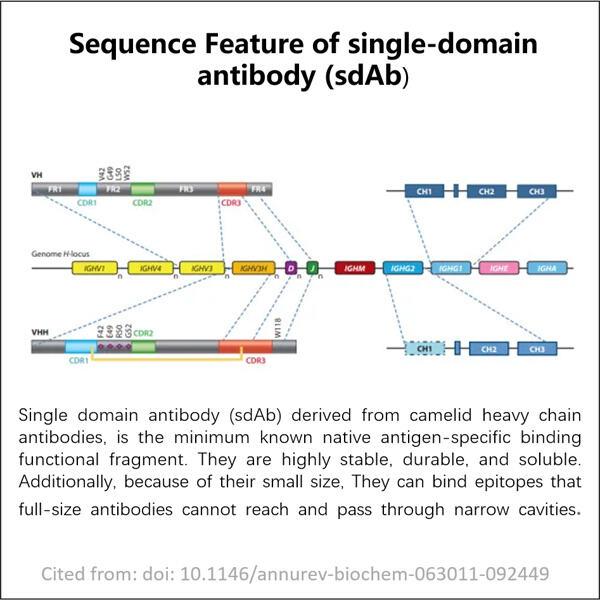

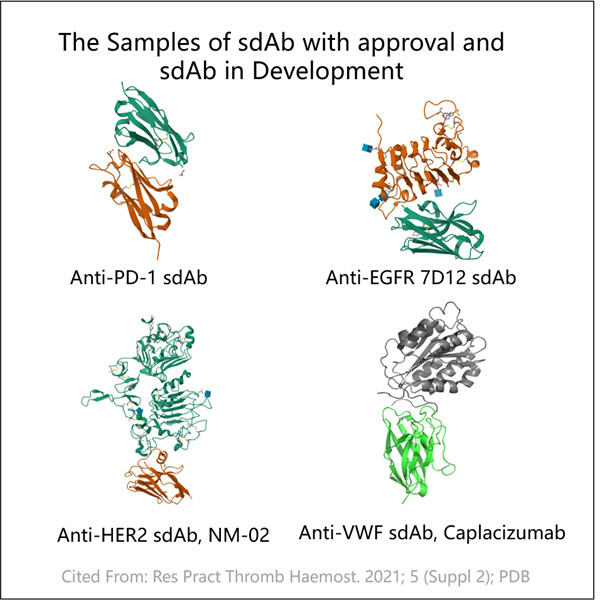

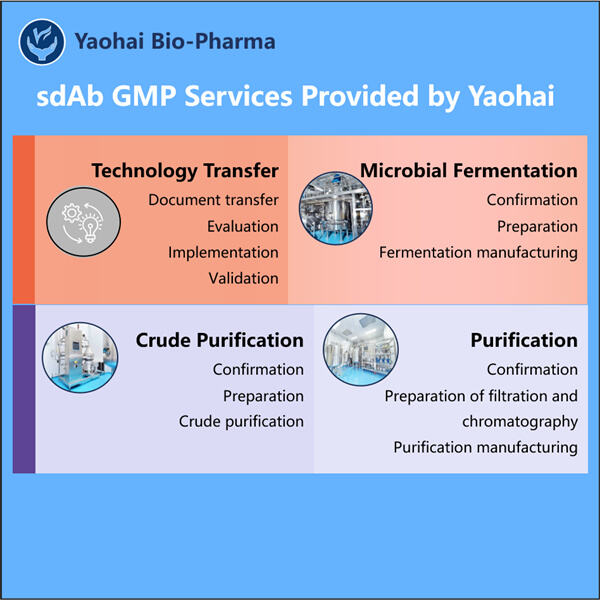

Yaohai Bio-Pharma has experience in the manufacture of biologics derived from microorganisms. We offer tailored RD solutions and manufacturing while minimizing the risk. We have worked with diverse methods, such as GMP sdAb Manufacturing of vaccines (including peptides), growth factors, hormones, and Cytokines. We specialized in multiple microbial hosts, including yeast extracellular and intracellular (yield up to 15 g/L) bacteria periplasmic secretion, soluble intracellular, and inclusion bodies (yield up to 10 grams/L). We also have a BSL-2 fermentation platform to create bacterial vaccines. We specialize in improving processes, increasing product yields, as well as reducing production costs. We have an efficient technology team that guarantees timely and quality project delivery. This allows us to deliver your exclusive products quicker to market.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NÃO

NÃO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN