Tilpasning, effektivitet og kostnadseffektivitet

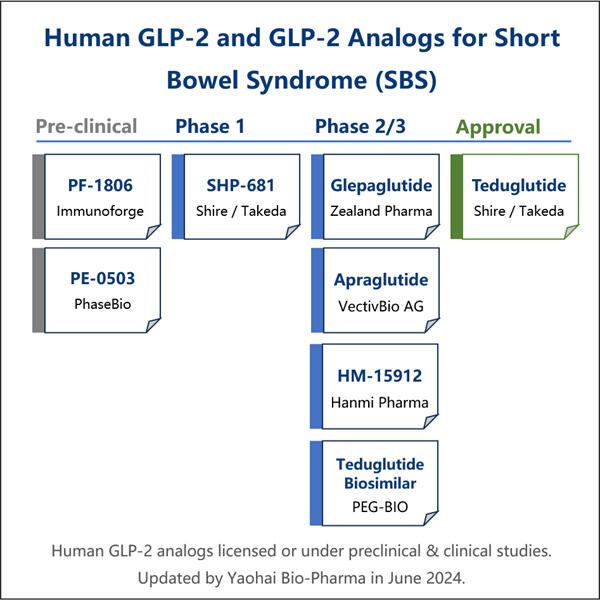

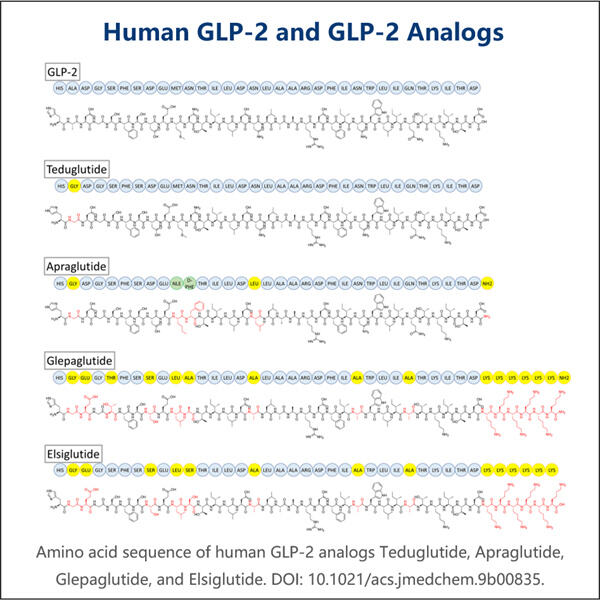

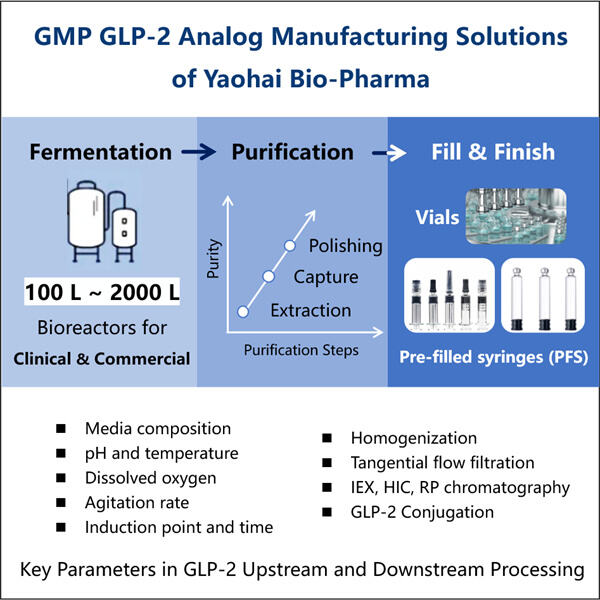

Yaohai Bio-Pharma is experienced in the development of microbial-derived biologics. We offer customized RD as well as manufacturing solutions, while making sure that there are no risks. We have worked on diverse modalities such as subunit-based recombinant vaccines, GLP-2 Analogue Biomanufacturing, cytokines, growth factors, single domain antibodies, enzymes, plasmid DNA, the mRNA, and other. We are experts in a variety of microorganisms, including yeast extracellular and intracellular secretion (yields up to 15g/L) as well as bacteria intracellular soluble and inclusion body (yields as high as 10g/L). We have also developed the BSL-2 fermentation platform to create bacteria-based vaccines. We have a track record of improving production processes, thereby increasing yields and decreasing costs. With a highly efficient technology team, we ensure timely and quality project delivery and bring your products to market faster.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NEI

NEI

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN