Professional Expertise & Extensive Experience

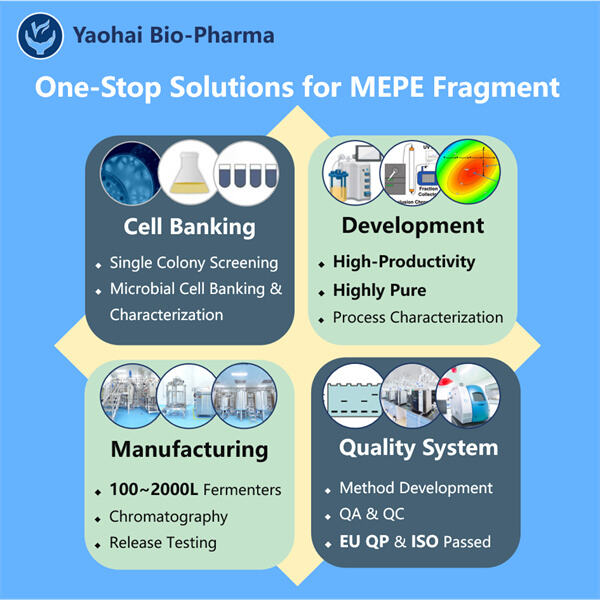

Yaohai Bio-Pharma, a leader in CDMOs for microbial biologics, is located in Jiangsu. We are focusing on microbially produced therapeutics and vaccines that are Recombinant MEPE Fragment Manufacturing for human, veterinary as well as pet health management. We have the most cutting-edge RD platforms as well as manufacturing technology that cover the entire manufacturing process, from microbial strain development, cell banking, process and method development to clinical and commercial manufacture which ensures successful production of novel solutions. We have gained an extensive amount of experience in bio processing of microbial cells. More than 200 projects have been successfully completed, and we support our clients in get through regulations, such as those of US FDA as well as EU EMA. We also aid them with Australia TGA and China NMPA. Our experience and professional knowledge as well as our extensive knowledge allow us to quickly respond to market demands and provide customized CDMO services.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN