The Significance of Upstream Process Development

Upstream process (USP), also known as fermentation process, is one of the initial phases of upstream bioprocessing. The microbial fermentation process is crucial for high-density cell culture and exogenous gene expression, which directly affects the biologics yield and cost.

In the early stages of biologics development (pre-clinical or phase 1/2), the focus is to develop scalable animal-free processes with intermediate yield and meet all product quality standards.

While in the late stages (phase 3 or commercial), we will focus on yield, robustness, scalability, and reproducibility, generating a cost-efficient process. The activities that address these issues are process characterization and process validation studies. Meanwhile, quality by design (QbD) and design of experiments (DoE) tools are typically applied.

Keywords: process development, optimization, and validation, process of fermentation, microbial cell fermentation, bacteria fermentation, yeast fermentation, high-density fermentation, engineered strain fermentation

Application: Biopharmaceutical industry, human medicine, animal medicine, vaccine, recombinant large molecule biologics, recombinant biologics, biological reagent

USP Solutions of Yaohai Bio-Pharma

Benefiting from over 10 years of microbial fermentation experiences, Yaohai Bio-Pharma has the expertise to help solve fermentation process challenges. We can rapidly establish high-density fermentation strategies for Escherichia coli (E. coli) periplasmic secretion, intracellular soluble or inclusion body expression, and Yeast extracellular or intracellular expression.

Our available general fermentation development services include:

- Fermentation process design performed at a small scale of 7L in fed-batch mode

- Three-batch process validation in 7L fermenters

- An intermediate process scale-up to 30L/70L

We can flexibly perform multi-parameter optimization to meet the desired yield or proportion, using One-Time-A-Factor (OTAF) or Design-of-experiments (DoE).

Key fermentation parameters are listed as follows:

Animal-free fermentation media compositions

Antibiotic-free or not, Inoculum volume

Growth temperature, pH, Dissolved oxygen (DO) level

Feeding mode (e.g., fed-batch)

Concentration of inducer (e.g., IPTG, methanol), Induction point (cell wet weight/OD600),

Induction temperature, Induction time

etc.

Service Details

| Services |

Process Flow |

| Cultivation in Shake Flask(500 mL) |

Animal-free media preparation → Cultivation of microbial seed → Cultivation in shaker → Induction → Harvest |

| Cultivation in Fermenter(7 L) |

Animal-free media preparation → Cultivation of microbial seed → High-density cell fermentation in 7L bioreactor → Induction → Harvest |

| Quality Control of Proteins/Peptides |

Pretreatment Intracellular soluble expression: Microbial cells harvest and resuspension → Ultrasonic crushing → Cell debris removal → Crude extract Inclusion body expression: Microbial cells harvest and resuspension → Ultrasonic crushing → inclusion body preparation→ Crude extract Extracellular soluble expression: Culture supernatant collection → Concentration and buffer exchange → Crude extract Quality analysis Crude extract as sample → Target protein analysis by SDS PAGE or Western blotting (WB) |

| Quality Control of Plasmids |

Pretreatment and Quality AnalysisPlasmid extraction → DNA analysis by agarose gel electrophoresis |

Case study

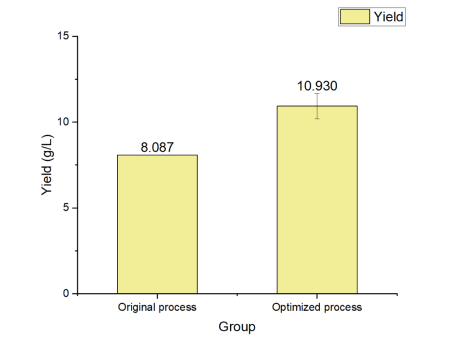

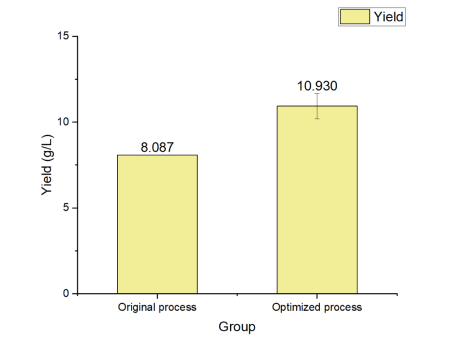

We are commissioned by our customer to increase the target polypeptide hormone yield from 8 g/L to 10 g/L.

Based on the Full Factorial Design and Response Surface Design in the DoE tools, we rapidly recognized and optimized the key fermentation parameters. Under the optimized high-cell density fermentation process, the expression level increased to 10 g/L.

Our experiences

- We have worked on various types of microbial hosts, e.g., E.coli DH5α, TOP10, Trans10, BL21; Pichia pastoris (P. pastoris) SMD1168H, X-33, GS115, PichiaPink strain1/2/3/4; Saccharomyces cerevisiae (S. cerevisiae) and Hansenula polymorpha (H. polymorpha).

- We are experienced with E. coli periplasmic secretion, soluble and inclusion body expression, as well as Yeast intracellular or extracellular expression. The yield of inclusion body is up to 10g/L, while soluble protein yield ranges from 0.5 to 15g/L.

- We have been involved in the development and manufacturing of various large molecules, including recombinant subunit vaccines, virus-like particles (VLPs), hormones (insulin, GLP-1, growth hormone), cytokines (Interleukin-2/IL-2, IL-15, IL-21), growth factors (EGF, FGF, NGF), nanobodies/ single-domain antibodies (sdAbs), enzymes, etc.

- Equipment

7L*16 Fermentation System

Cedex Bio Analyzer, Bioprocess analyzer

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN