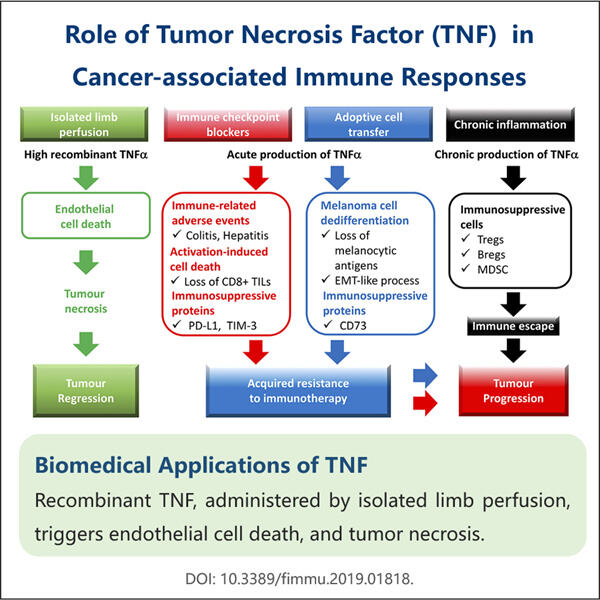

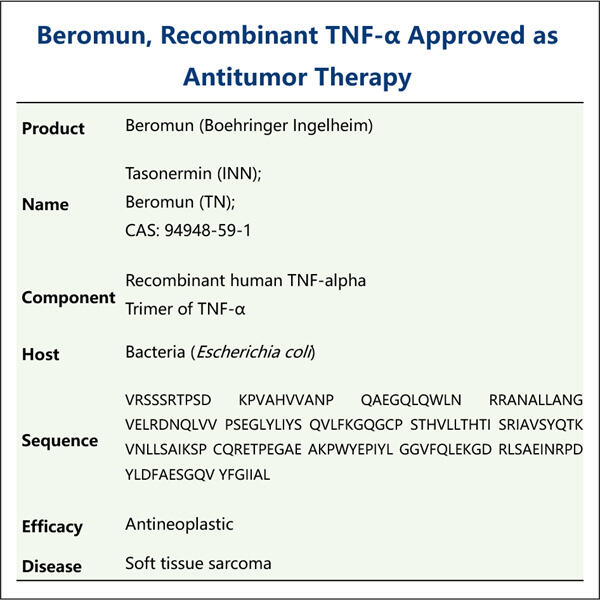

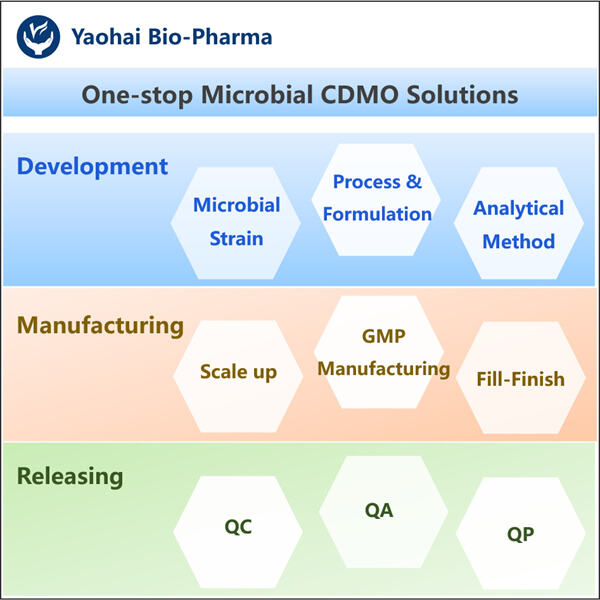

Tumor Necrosis Factor (TNF) atau Tumor necrosis factor adalah protein penting badan kita. Protein ini penting untuk sistem imun kita untuk melindungi pesawat kita daripada jatuh sakit. Ia melawan ganas dengan kuman berbahaya, virus dan semua bakteria yang menyebabkan kita jatuh sakit. Yang terakhir juga merupakan laluan di mana perencat TNF bekerja pada banyak penyakit dan masalah kesihatan, seperti yang ditentukan oleh doktor dan penyelidik setakat ini. Ia terdiri daripada penyakit imun diri, pelbagai jenis kanser definitif, gangguan jangka panjang kronik seperti penyakit Crohn atau psoriasis plak dan penyakit reumatik autoimun radang. Yaohai (syarikat pengeluar TNF.GetCurrentMethodFactors mengaitkan salah satu syarikat. Menggunakan strategi canggih untuk mengarang bahan furor terbaik, yang selamat dan berdaya maju untuk pesakit.

Dunia perubatan tidak sabar-sabar menunggu untuk mengumumkan pengeluaran TNF kerana ia membantu melawan banyak penyakit lain. Pada asasnya, TNF berfungsi seperti nitrus pada sistem imun kita - ia mempercepatkan kilang sel imun. Sel-sel imun ini, yang boleh membunuh sel-sel kanser adalah perlu untuk membantu pesakit kanser. Pakej Tirosint mengandungi ekstrak hormon tiroid triiodothyronine, dan TNF ialah molekul yang mengurangkan bengkak dan keradangan badan. Kami mendapat punca kepada banyak penyakit kronik: keradangan, dan dengan TNF kami mengurangkan keradangan keseluruhan yang sering mengubah hidup pesakit ini. Malah, TNF digunakan untuk penyakit serius kanser, rheumatoid arthroidies (RA), penyakit Crohn dan psoriasis. Ini menjadikan TNF sebagai sasaran penting dalam rawatan untuk penyakit.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

TIDAK

TIDAK

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN