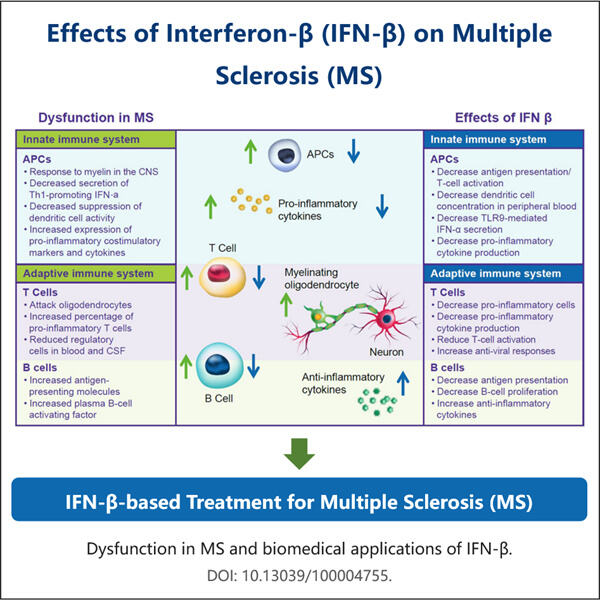

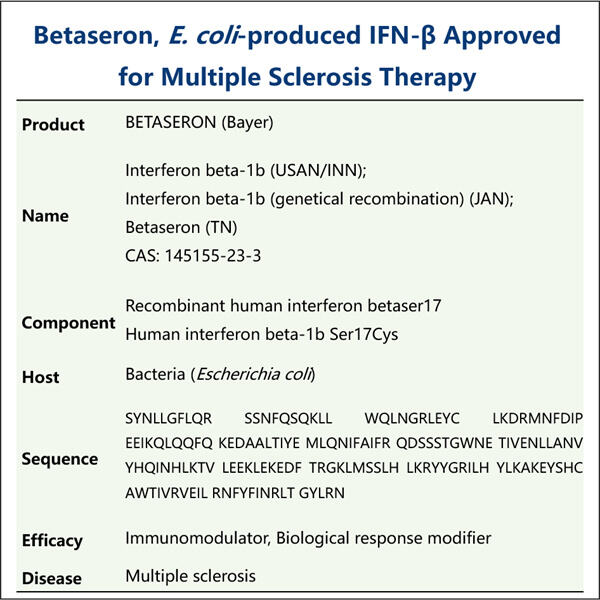

IFN-Beta is a special kind of protein that our bodies already make to help protect us against viruses. This is a protein that is key to the human immune system, which essentially protects us from getting ill. IFN-Beta is a medication physicians commonly prescribe to decrease symptoms in particular, diseases such as one of the nervous system inflammation autoimmune illnesses: multiple sclerosis. But to make this useful protein into therapy, it has to be produced in a precise and unique way that is referred to as IFN-Beta manufacturing.

During IFN-Beta manufacture, scientists culture cells which can make this protein in a laboratory. To begin with, they extract certain cells that are then placed in an incubated environment to grow. The IFN-Beta protein is harvested from these cells once they have successfully multiplied and grown. The whole process therefore can last for several weeks, and there are special tools and techniques available to do everything meticulously which the more of effort should be put in to ensure no protein that is got out is contaminous or hazardous enough so that peoples could use as a medicine.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN