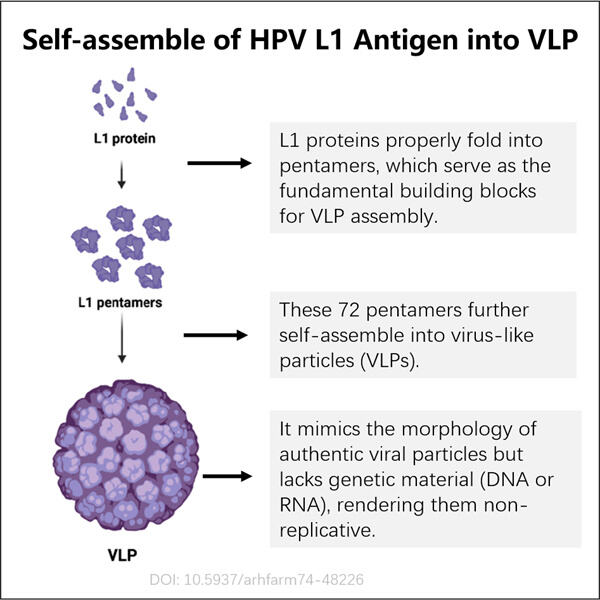

Έχεις ακούσει ποτέ για το HPV; Το HPV σημαίνει (Υποδερμικό Φυματώδες Ιος). Κάποιες ειδικές τύποι του HPV μπορούν επίσης να προκαλούν καρκίνο. Αλλά μην αγωνίζεσαι! Στα τελευταία χρόνια, στην εταιρεία Yaohai, οι επιστήμονες έχουν περάσει αριθμητές ανάπαυσης νύχτες προσπαθώντας να παράγουν μια εμβολία που μπορεί να θεραπεύσει λοιμώξεις HPV. Αυτό το τελευταίο σημείο είναι κρίσιμο, καθώς μια εμβολία διδάσκει τα σώματα μας να αναγνωρίζουν πώς να αντιμετωπίσουν αυτούς τους ιούς. Διαδικασία Παραγωγής Υψηλής Απόδοσης Plasmid . Μια σημαντική φάση στην ανάπτυξη αυτού του εμβολίου είναι η δημιουργία ούτως λεγόμενων αντιγόνων HPV. Οι αντιγόνοι είναι μοναδικά πρωτεΐνα που το σώμα μας τα αναγνωρίζει ώστε να κατασκευάσει άμυνα και να αγωνιστεί ενάντια στον ιό. Εδώ είναι πώς παράγει μια σειρά από αυτούς τους κρίσιμους αντιγόνους, χρησιμοποιώντας τους έναν ένα.

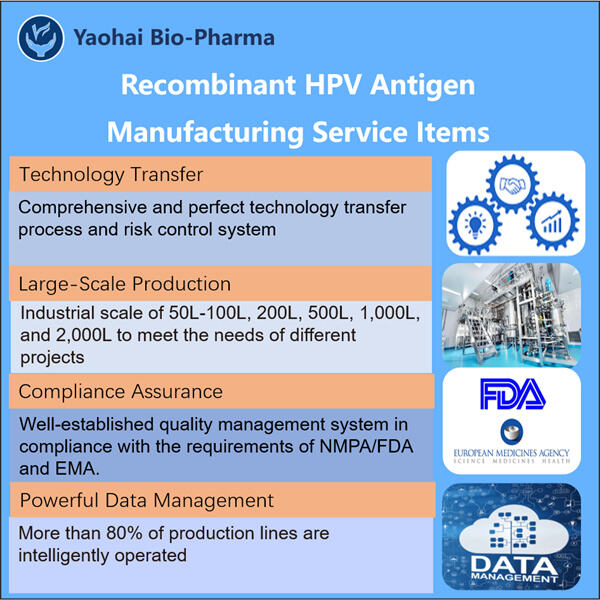

Οι συστατικές των αντιγόνων HPV που χρησιμοποιούνται από παράγονται με τη χρήση μάγειρας – μικροσκοπικών ζωντανων οργανισμών. Η μάγειρα είναι ένας μύκητας που, εκτός από το γεγονός ότι κάνει να γεύεται καλά το ψωμί και το μπύρα, μπορεί επίσης να είναι ωφέλιμη για επιστημονική έρευνα. Δημιουργούν πρώτα μια μεταγενετικά τροποποιημένη μάγειρα που μπορεί να παράγει τους αντιγόνους τούς οποίους ενδιαφέρονται. Αυτό είναι το διαδικασίας της γενετικής τροποποίησης. Στη συνέχεια προσθέτουν τη μάγειρα σε μεγάλα δοχεία που γεμίζονται με ένα είδος τροφής που ονομάζεται «γλυκά», και αυτό τους βοηθά να γίνουν ισχυρότεροι. Τα δοχεία ή κατασταλτικά. Μόλις μπουν στα δοχεία, η μάγειρα αναπτύσσεται και πολλαπλασιάζεται — παράγοντας αντιγόνους HPV που μπορούν να συγκεντρωθούν από το δοχείο.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN