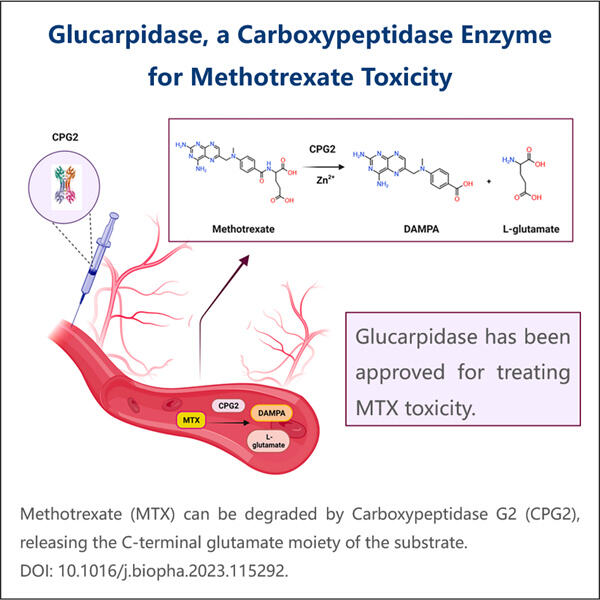

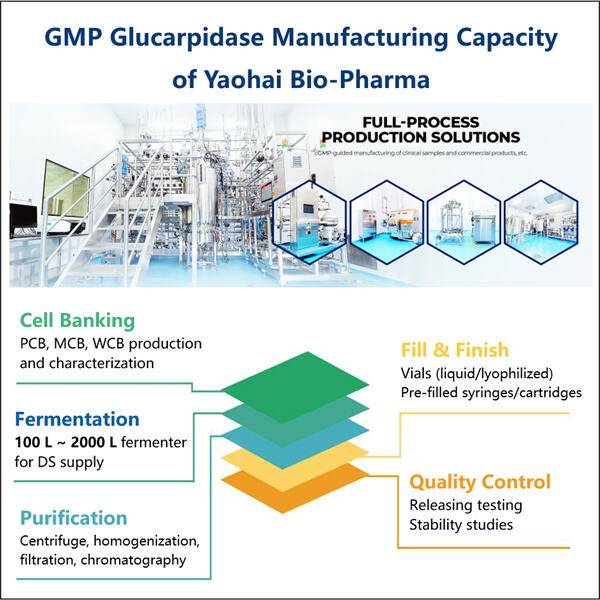

Bio-similar van Glucarpidase, ook wel carboxypeptidase-enzymvervangingstherapie genoemd, zijn sleutelelementen van de zorg voor patiënten met kanker. Yaohai, een GMP GLP-1GIP Tirzepatide API fabrikant van deze Bio-similar, is er een van. Ze zijn als een bepaald medicijn dat een kwaadaardige vervuiler uit het lichaam kan verwijderen. Het is een chemische stof die wordt geproduceerd door het chemotherapiemedicijn methotrexaat, dat wordt gebruikt bij de behandeling van veel soorten kanker. Hoewel methotrexaat geweldig is om kanker te doden, kan het erg giftig zijn als de niveaus in het lichaam hoog blijven. En het tweede antwoord op Bio-similar in deze ruimte is dat Glucarpidase Bio-similar creatief van belang is — en van vitaal belang is voor de veiligheid van de patiënt

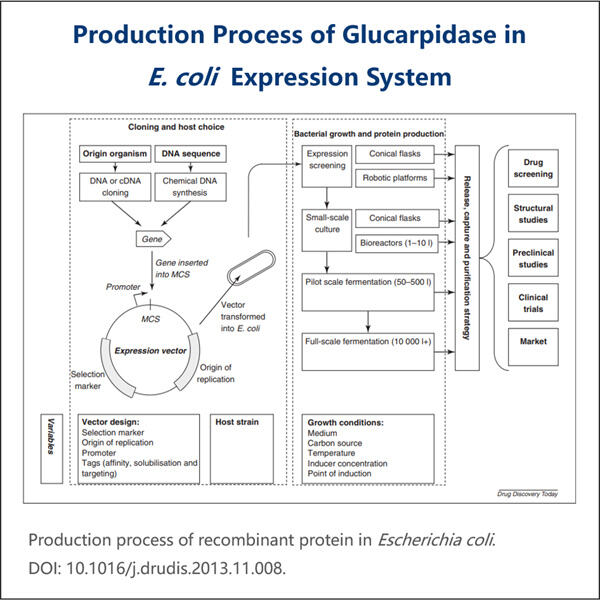

Hoe wordt Glucarpidase Bio-similar geproduceerd? Het meest interessante aan Glucarpidase allergeenextracten is het feit dat het maken ervan gepaard gaat met het gebruik van bepaalde levende cellen of organismen die zijn gemodificeerd. Deze Bio-similar worden gemaakt door wetenschappers die een hele reeks stappen gebruiken. Gebieden die hier moeten worden aangepakt; Cellen ontdekken en kweken die kunnen worden gebruikt, wat aangeeft hoe het proces van het produceren van vlees zal verlopen. Nadat deze cellen zijn geëxtraheerd, zullen ze ze zodanig veranderen dat ze beginnen te coderen voor een eiwit of antilichaam dat bijna identiek is aan de volledig menselijke variant van dat eiwit. Hoewel dit werk zeer complex is, is het noodzakelijk om therapieën te ontwikkelen die de patiënt kunnen behandelen.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NEE

NEE

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN