Pembuatan Mikroba Memimpin

6 Pembuatan Mikroba digunakan oleh lebih banyak perusahaan

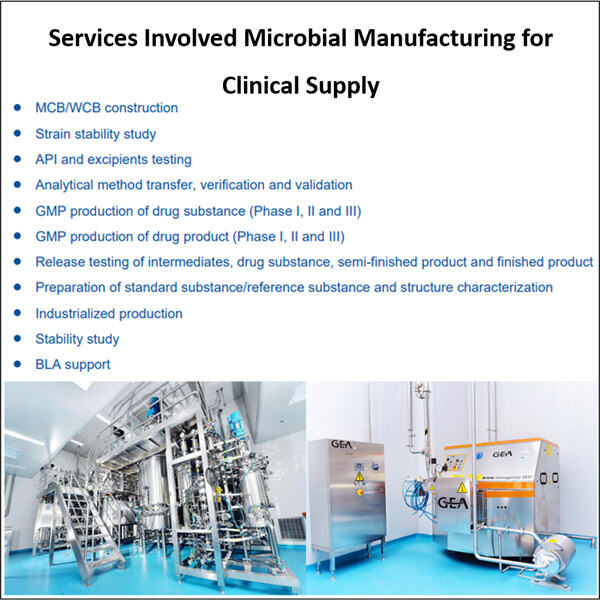

Sebagai hasilnya, pabrik-pabrik masa depan yang memproduksi obat-obatan secara otomatis, beralih ke pembuatan mikroba karena metode yang lebih cepat dan efisien. Sebagai contoh, mereka dapat menghasilkan kuantitas besar zat obat dalam beberapa minggu daripada menunggu selama berbulan-bulan.

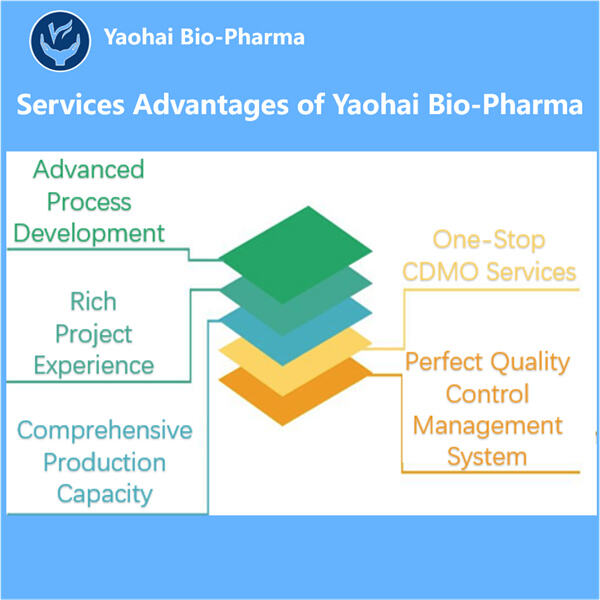

Semangat premium untuk Tune Medicinal adalah alasan mengapa Yaohai percaya pada kualitas ketika berbicara tentang obat-obatan. Itulah sebabnya kami memfermentasi produk kami dengan cara yang tidak dilakukan oleh siapa pun, hanya menggunakan pembuatan mikroba. Metode ekstraksi milik kami sendiri memungkinkan kami menghasilkan obat berkualitas tinggi dengan cepat dan terjangkau untuk masyarakat.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN