The basis of encapsulation is the design and development of the delivery system. A well-designed delivery system allows mRNA molecules to enter the body without being degraded by RNase, and then be effectively delivered to the target site, cross the cell membrane and be released intracellularly. Lipid nanoparticles (LNPs) are the optimal delivery systems available, with advantages in terms of encapsulation, delivery, and safety compared to other delivery systems. LNPs with nucleic acid fragments are easily swallowed into cells and form intracellular bodies. Once inside the cell, the acidic environment of the intracellular body protonates and positively charges the head of the ionized lipid, which fuses with the inner membrane of the intracellular body and releases the target nucleic acid into the cell for action.

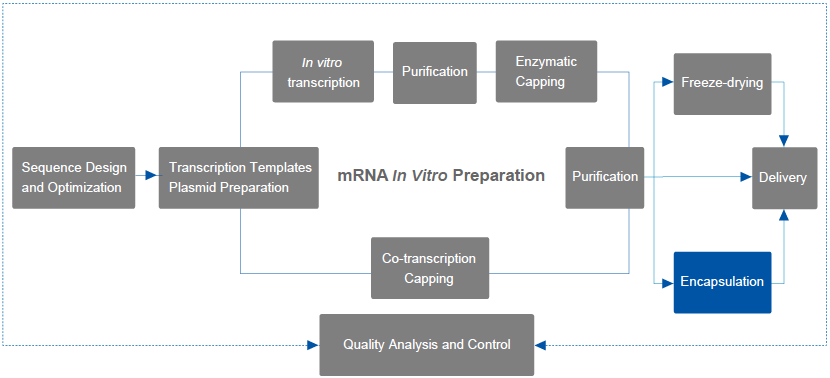

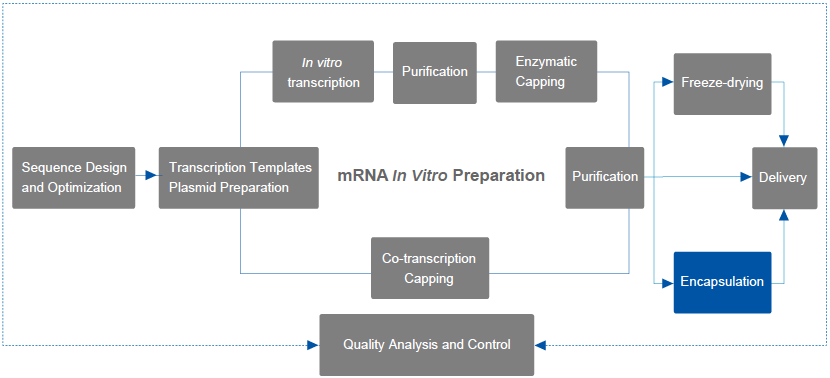

Yaohai Bio-Pharma mRNA service continues to improve, and now can provide mRNA-LNP encapsulation service, optimize relevant critical process parameters, and improve the consistency and reproducibility of mRNA drug production.

Services Details

| Service | Service Details | Delivery Period (Workday) | Deliverables |

| mRNA-LNP encapsulation | Preparation of water phase (mRNA) and lipid phase | 2 | mRNA-LNP drug product (DP) |

| Microfluidic device mixing |

| Ultrafiltration concentration | 1 |

| Sterilizing filtration |

| mRNA-LNP quality control | Encapsulation efficiency | 1 | Test Report |

| Particle size and distribution detection |

| Surface charge detection |

| mRNA-LNP expression validation | 5-7 |

Our Features

Fast synthesis speed, high R&D efficiency and pre-optimized solutions available.

mRNA-LNP encapsulation rate can reach more than 90%.

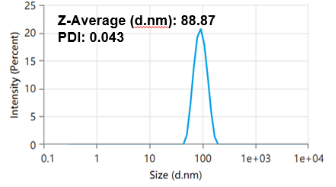

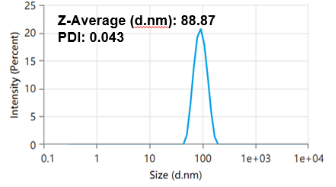

By changing the fluid injection rate and ratio, the LNP particle size is controlled between 80 and 100nm, and the particle size distribution is uniform (PDI<0.10).

mRNA-LNP is validated by in vitro cell expression and can express the target protein efficiently.

Case study

With the help of Yaohai Bio-Pharma's microfluidic encapsulation platform, we optimized the mRNA encapsulation conditions, including the ratio of each component of LNP, the ratio of aqueous phase to organic phase, and the flow rate of each microfluidic phase. The particle size and particle size distribution of the finished mRNA-LNP were then detected.

Experimental results show that through preparation formulation and process optimization, we control the LNP particle size to 80~100nm, and the dispersion coefficient (PDI) is 0.043, indicating that the LNP size distribution is uniform.

Analysis of a mRNA-LNP sample

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN