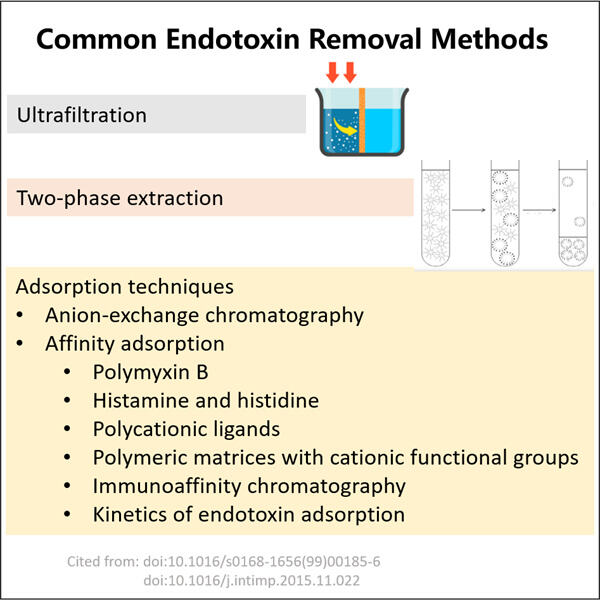

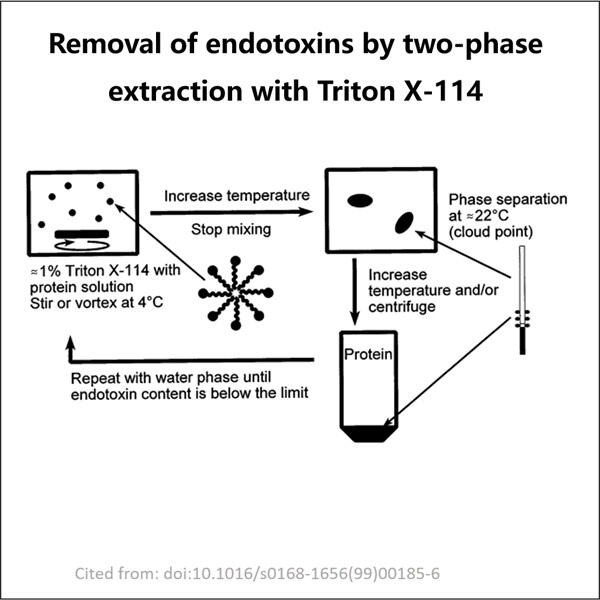

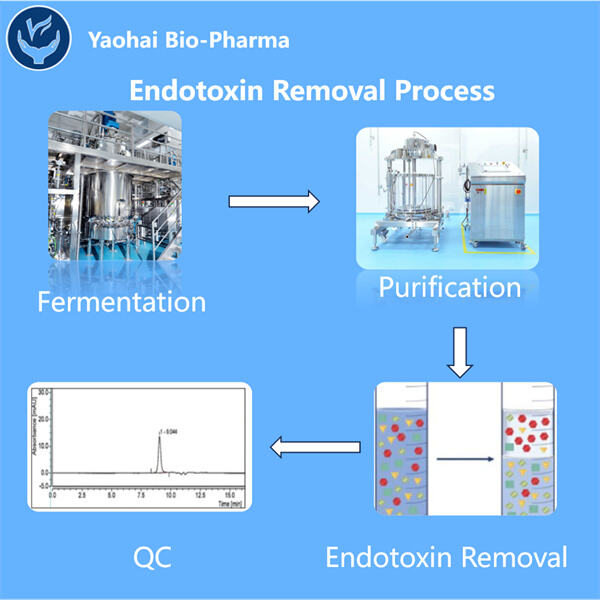

Endotoxins are minuscule molecules found in numerous forms of existing life, such as your body and those of animals. They are teeny enough invisible to the human eye but can do so much damage. Endotoxins, when not eliminated properly from either humans or animals, is considerably bad. All things considered, this is why eliminating endotoxins is imperative. It is a life and death situation that should be handled with respect.

In order to explain how we eliminate endotoxins, it is important that you know what these are. Endotoxins are a unique class of molecules that are made by some bacteria. These bacteria are ubiquitous, and can be found in soil, water and even inside our bodies. As these bacteria die, they release endotoxins into their immediate environment.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

TIDAK

TIDAK

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN