|

Process

|

Services Details

|

Unit Operation

|

|

Technology Transfer

|

Document transfer

|

Process, formulation, analytical methods and quality standard

|

|

Technical and compliance evaluation

|

Evaluation of man-machine-material-method-environment-measurement;

Evaluation of process, formulation, analytical methods and quality standard.

|

|

Technology transfer implementation

|

Manufacturing process and analytical transfer

|

|

Process validation

|

1~3 engineeringbatchesto evaluate and confirm the process is robust.

|

|

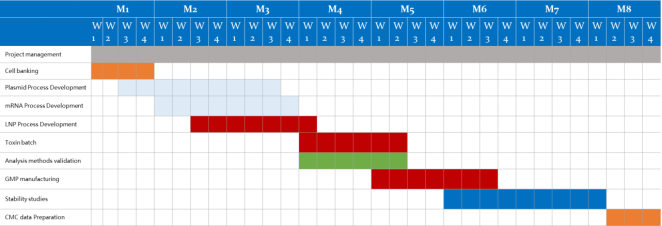

Plasmid Manufacturing

|

E. colifermentation

|

Preparation of fermentation system

|

|

Seedcultivation, fed-batch fermentation

|

|

Plasmid purification

|

E. colicell harvesting and alkaline lysis

|

|

Plasmid purification, impurities removal

|

|

Plasmid linearization

|

Single enzyme digestion

|

|

Purification of linearized template plasmid

|

|

mRNA DS Manufacturing

|

mRNA synthesis

|

In vitrotranscription (IVT) reaction

|

|

mRNA purification

|

DNA template removal

|

|

mRNA purification, impurities removal

|

|

mRNA buffer exchange

|

Tangential flow filtration

|

|

LNP DS Manufacturing

|

LNP encapsulation

|

Preparation of ethanol phase containing lipids

|

|

Microfluidics technology

|

|

Concentration and buffer exchange

|

Tangential flow filtration

|

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN